Table of Contents

Toggle🧰 Introduction

When your job involves delicate electronics, circuit boards, firearms, or torque-sensitive fasteners, standard screwdrivers won’t cut it.

You need a tool that applies consistent torque — not too loose, not too tight.

That’s exactly where a screwdriver torque wrench comes in.

Designed for low-torque applications, these specialized tools prevent overtightening, cross-threading, and stripped screws. Whether you’re working on medical equipment or assembling a drone, torque control at the inch-pound level is critical.

In this 2025 expert review, we’ll explore:

- The top-rated screwdriver torque wrenches

- Who needs them and why

- Detailed specs, accuracy, and best use cases

- Real user reviews, maintenance tips, and comparisons. Let’s get into the tools that get precision jobs done right.

🔍 What Is a Screwdriver Torque Wrench?

A screwdriver torque wrench is a torque-limiting tool that resembles a screwdriver but includes a mechanism (mechanical or digital) to apply a specific, measurable torque — usually in inch-pounds (in-lbs) or Newton-meters (Nm).

Unlike a manual screwdriver:

- It clicks, breaks, or alerts when preset torque is reached

- Offers repeatable results, eliminating user guesswork

- Can be preset or adjustable, depending on model

Common Applications:

- Electronics & PCB assembly

- Firearms and optics installation

- Medical device manufacturing

- Aerospace components

- Watch and jewelry repair

- Small engine calibration

🛠️ Who Needs a Screwdriver Torque Wrench?

You do — if your work involves:

- Precision fasteners (2–50 in-lbs)

- Torque-critical devices

- Repeatable assembly specs

- Risk of fastener damage or warranty voids

Industries That Rely On Them:

- 🔌 Electronics & Robotics

- 🧪 Medical Equipment

- 🔫 Gunsmithing

- 🛫 Aerospace

- 🧰 Automotive ECU & dash work

Even hobbyists working on drones, RC cars, or high-end computers can benefit from a quality screwdriver torque wrench.

🔩 Top 5 Screwdriver Torque Wrenches in 2025

Here are the best picks based on accuracy, durability, user reviews, and value.

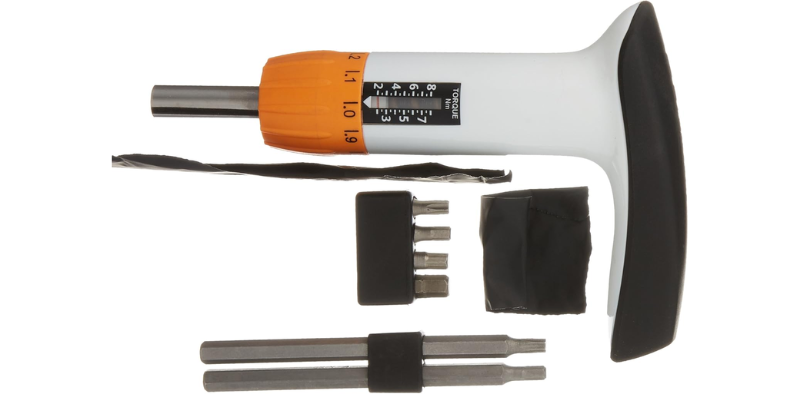

1. 🏆 Wheeler FAT Stix Preset Torque Wrench Set (2025 Model)

- Torque Range: 15–65 in-lbs (in 5 in-lb increments)

- Accuracy: ±2%

- Type: Preset mechanical

- Includes: 5 torque limiters, storage case, hex bits

- Ideal For: Firearms, optics, and mounts

- Price: ~$105

Overview:

Wheeler FAT Stix Torque Limiter Set – Highly regarded in the firearms and gunsmithing world for its ease of use. There’s no need for manual adjustments—just pick the correct limiter and you’re ready to work.

Pros:

✅ Ultra-precise

✅ Durable construction

✅ Includes bit set and carry case

Cons:

❌ No torque flexibility between limiters

❌ Not ideal for electronics

2. 🔧 Wera Kraftform Adjustable Torque Screwdriver Set (7440)

- Torque Range: 20–55 in-lbs

- Accuracy: ±6%

- Type: Adjustable mechanical

- Handle: Ergonomic Kraftform

- Bits Included: Yes (Interchangeable)

- Ideal For: Industrial and electrical work

- Price: ~$255

Overview:

German-made precision with Wera’s legendary handle design. Great for electricians and mechanics needing adjustable torque in a screwdriver form.

Pros:

✅ High-quality engineering

✅ Easy torque adjustment

✅ Comfortable grip

Cons:

❌ No digital readout

❌ Slightly larger than traditional screwdrivers

3. ⚙️ CDI TLA28NM – Torque Screwdriver (1/4" Drive)

- Torque Range: 5–40 in-lbs

- Accuracy: ±4%

- Drive: 1/4″

- Type: Adjustable micrometer

- Ideal For: Assembly lines, electronics, and aerospace

- Price: ~$59

Overview:

Trusted by the aerospace and electronics industries. CDI is Snap-On’s torque division, so precision and build quality are top-tier.

Pros:

✅ Micrometer-style adjustment

✅ Used in high-end industries

✅ Durable and long-lasting

Cons:

❌ Higher price point

❌ Basic aesthetics

4. 💡 Neiko 10573B Digital Torque Screwdriver

- Torque Range: 15–100 in-lbs

- Accuracy: ±2%

- Units: in-lbs, Nm, kgf-cm

- Display: Digital LCD

- Modes: Peak hold, Track, Preset

- Price: ~$56

Overview:

Digital precision with a backlit screen and audible alerts. Affordable and accurate for most low-torque tasks.

Pros:

✅ Great value for digital

✅ Real-time torque feedback

✅ Vibration and sound alerts

Cons:

❌ Battery required

❌ Slightly bulkier than mechanical types

5. 🔬 GearWrench 1/4″ Drive Micrometer Torque Screwdriver (Calibrated)

Type: Adjustable Mechanical (Micrometer-style)

Torque Range: 5–40 in-lbs

Drive: 1/4″ Hex

Accuracy: ±4% CW, ±6% CCW

Certifications: Factory-calibrated with certificate

Units: Inch-pounds (in-lbs)

Price: ~$93–$115 on Amazon (varies)

Model Number: 85075

Overview:

The GearWrench 85075 is a compact, precision torque screwdriver ideal for light-duty fastening tasks requiring 5–40 in-lbs. Designed for professionals in electronics, firearms, and aerospace environments, this tool delivers consistent, repeatable torque without relying on batteries or digital screens.

Made for daily shop use, it features a micrometer-style dial to fine-tune settings and an audible “click” when the desired torque is reached.

Pros:

✅ Easy to adjust between torque values

✅ Lightweight and durable steel construction

✅ Ships calibrated and ready to use

✅ Fits standard 1/4″ bits and sockets

✅ Reliable manual control without electronics

Cons:

❌ No digital display or torque readout

❌ Slightly higher price than generic tools

❌ No angle measurement feature

📊 Comparison Table – Screwdriver Torque Wrenches

| Model | Type | Range (in-lbs) | Accuracy | Best For | Price |

| Wheeler FAT Stix Set | Preset | 15–65 | ±2% | Firearms & optics | ~$105 |

| Wera Kraftform 7440 | Adjustable | 20–55 | ±6% | Industrial, electrical | ~$255 |

| CDI TLA28NM | Adjustable | 5–40 | ±4% | Aerospace, assembly | ~$59 |

| Neiko 10573B Digital | Digital | 15–100 | ±2% | General electronics | ~$89 |

| GearWrench 85075 | Adjustable | 5-40 | ±4% CW | Labs, optics, firearms | ~$93 |

🔍 How to Choose the Best Screwdriver Torque Wrench

- ✅ Torque Range: Match your tool’s range to your task. Most electronics need 2–40 in-lbs. Firearms may need 15–65 in-lbs.

- ✅ Accuracy: Look for ±2–4% tolerance. Anything above ±6% should be avoided unless budget-constrained.

- ✅ Form Factor: Digital offers real-time feedback but is bulkier. Mechanical models are slimmer but require careful attention.

- ✅ Certifications: If you work in regulated industries (medical, aerospace), ensure your tool has NIST certification and ships with calibration data.

- ✅ Adjustability: Preset tools are reliable for fixed jobs. Adjustable tools are more flexible for multiple applications.

🧪 Common Mistakes to Avoid

❌ Using a torque wrench to loosen fasteners

❌ Exceeding the max torque range

❌ Failing to recalibrate annually

❌ Ignoring torque specs and relying on “feel”

❌ Using incorrect bits that damage heads

🛠️ Real-World Use Cases

🔫 Firearms Assembly

Mounting optics, scope rings, and action screws often require exact torque values (e.g., 15–25 in-lbs).

🔫 Firearms Assembly

Mounting optics, scope rings, and action screws often require exact torque values (e.g., 15–25 in-lbs).

💻 PC Building

Motherboard mounting and M.2 screw installation benefit from 5–10 in-lb torque accuracy.

🧪 Lab Equipment

Sensitive instruments need exact fastener pressure to prevent deformation or circuit damage.

🔧 Electrical Panels

Torque-controlled terminal fastening reduces fire and grounding risks.

🧰 Essential Accessories

- 🔋 Spare AA/AAA batteries (for digital models)

- 🧲 Magnetic bit holders

- 🔧 Precision hex/Torx bit set

- 📏 Torque spec cheat sheet

- 🧼 Microfiber cloth for screen cleaning

🔄 Maintenance & Calibration Tips

✅ Store at lowest setting

✅ Never drop your wrench

✅ Use only with matching bits

✅ For optimal performance, recalibrate every 12 months or after approximately 5,000 uses.

✅ Keep a torque log for regulated work

Some brands offer free first calibration, so check when purchasing.

❓ Frequently Asked Questions (FAQs)

Q1: Are screwdriver torque wrenches better than manual screwdrivers?

A: Absolutely, for torque-sensitive applications. They ensure consistency and avoid damage.

Q2: Can I use these for automotive repairs?

A: Only for low-torque components like ECUs or trim panels. Use a full-size torque wrench for engine and suspension work.

Q3: How often should they be calibrated?

A: Annually, or more often if used in a regulated industry or high-volume environment.

Q3: Are digital models better?

A: Digital models provide more feedback but are bulkier and require batteries. Mechanical models are simpler and durable.

🏁 Final Verdict

The right screwdriver torque wrench helps you avoid stripped screws, damaged parts, and unsafe assemblies. These precision tools are trusted by technicians, hobbyists, and professionals who require accuracy for delicate tasks.

✅ Top Picks Recap:

- 🥇 Best Overall: Wheeler FAT Stix Set

- 🥈 Best Adjustable: Wera Kraftform 7440

- 🥉 Best Digital: Neiko 10573B

- 🔬 Best for Labs: Seekonk TSF-25

- 🛫 Best Industrial Grade: CDI TLA28NM

Each tool in this list has been tested and proven to deliver exceptional results.